|

Detailed introduction/parameters/applications/functions/maintenance of AlN Aluminum Nitride Ceramic Sheet Plate Substrate

▼ Material Description

When it comes to providing good thermal conductivity and high electrical insulation features, aluminum nitride substrate is a superb option because of its efficacy. Aluminum nitride sheets are widely used in the semiconductor application industry instead of beryllium oxide (BeO) since aluminium nitride is non-toxic and does not produce dangerous vapors when grinded and machined. Aluminum nitride ceramic substrate has a thermal expansion and isolation coefficient which closely matches the silicon wafer product, making it useful in applications in electronics that often have high temperatures and heat dissipation problems.

▼ Surface Roughness of Ceramic Substrates

All substrates are grinded with surface roughness Ra0.3-0.6. We can also do surface polishing, one-side polishing or double-side polishing with surface roughness Ra0.02-0.05.

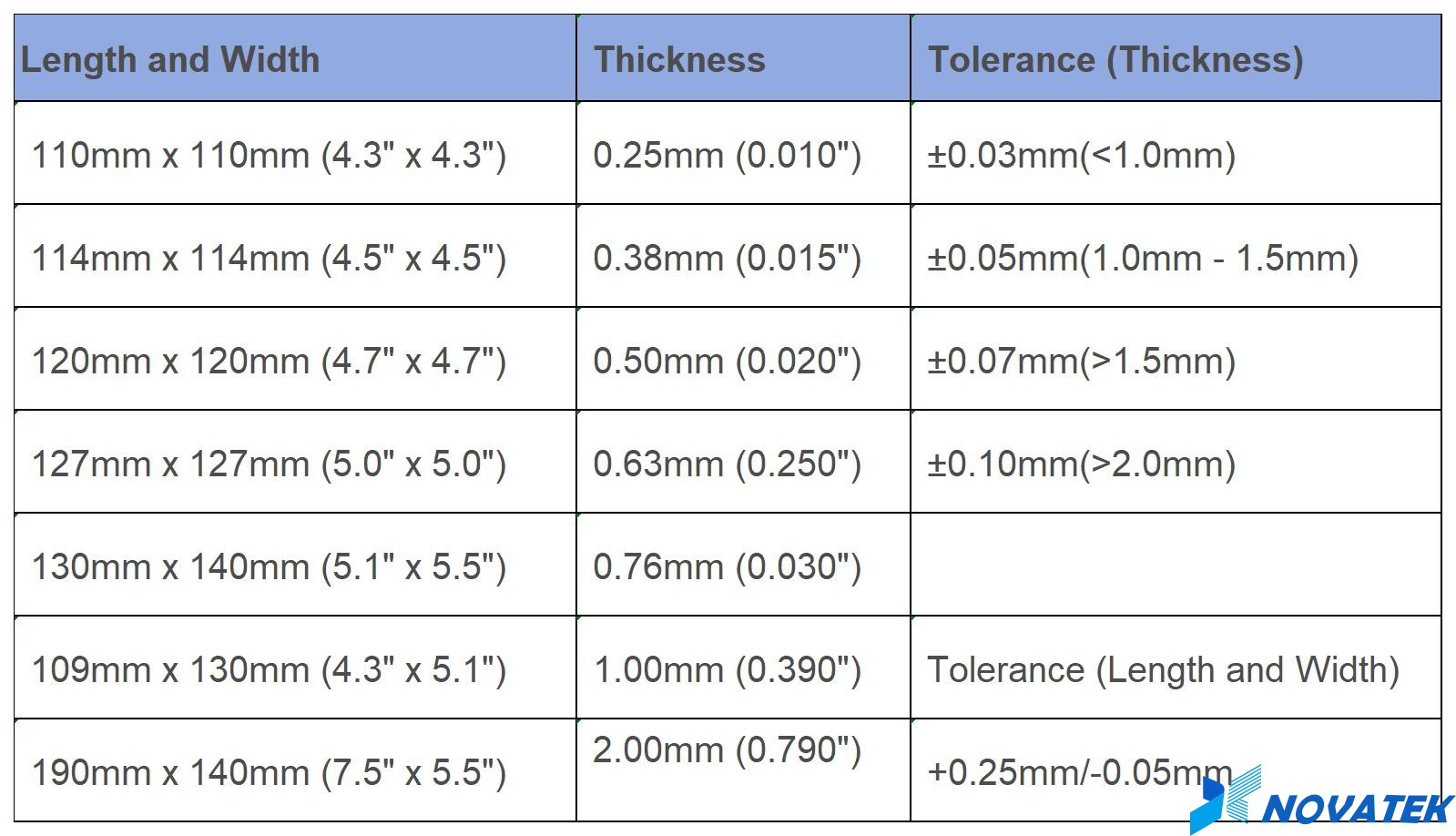

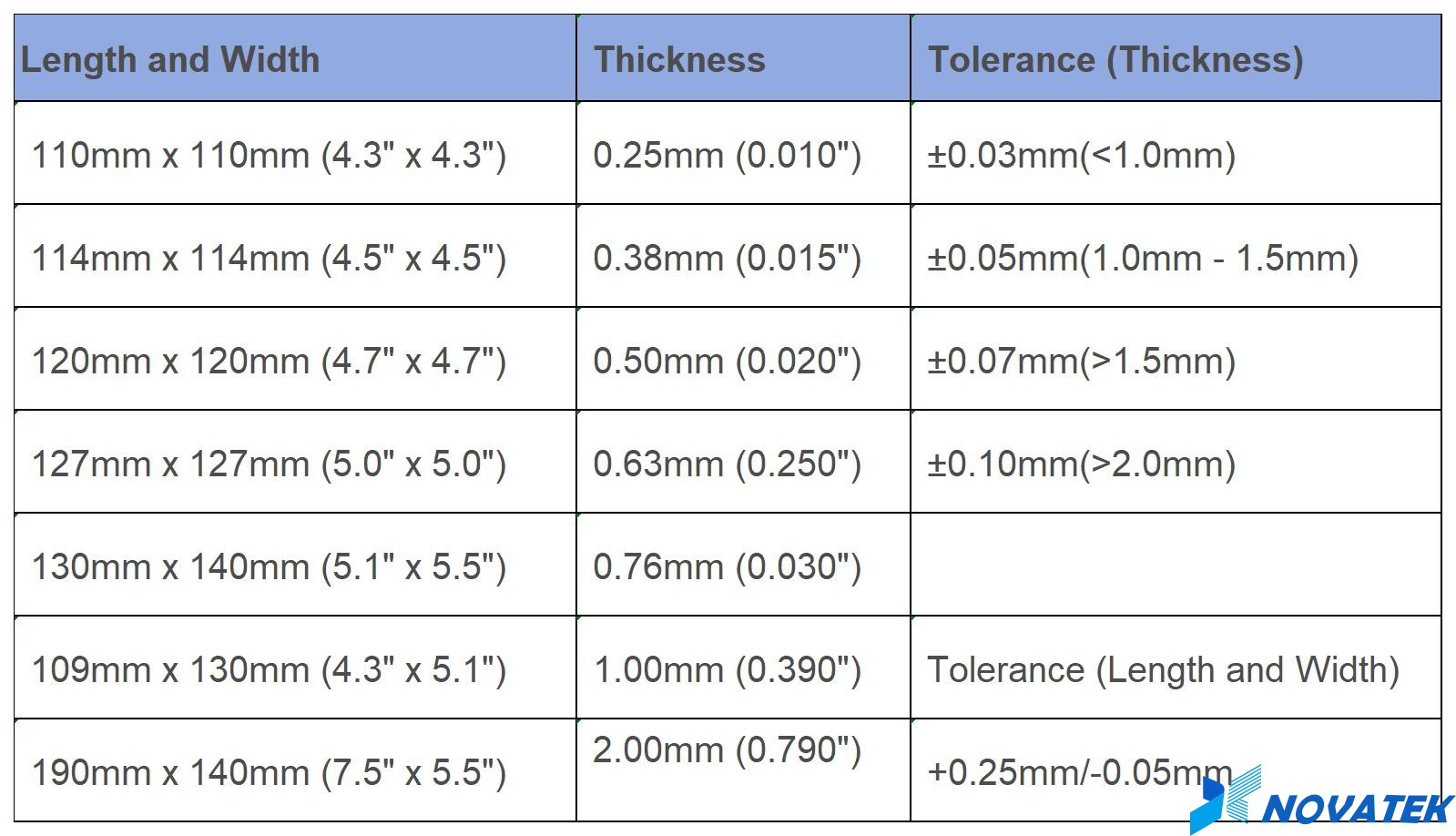

▼ Standard Dimensions and Tolerance

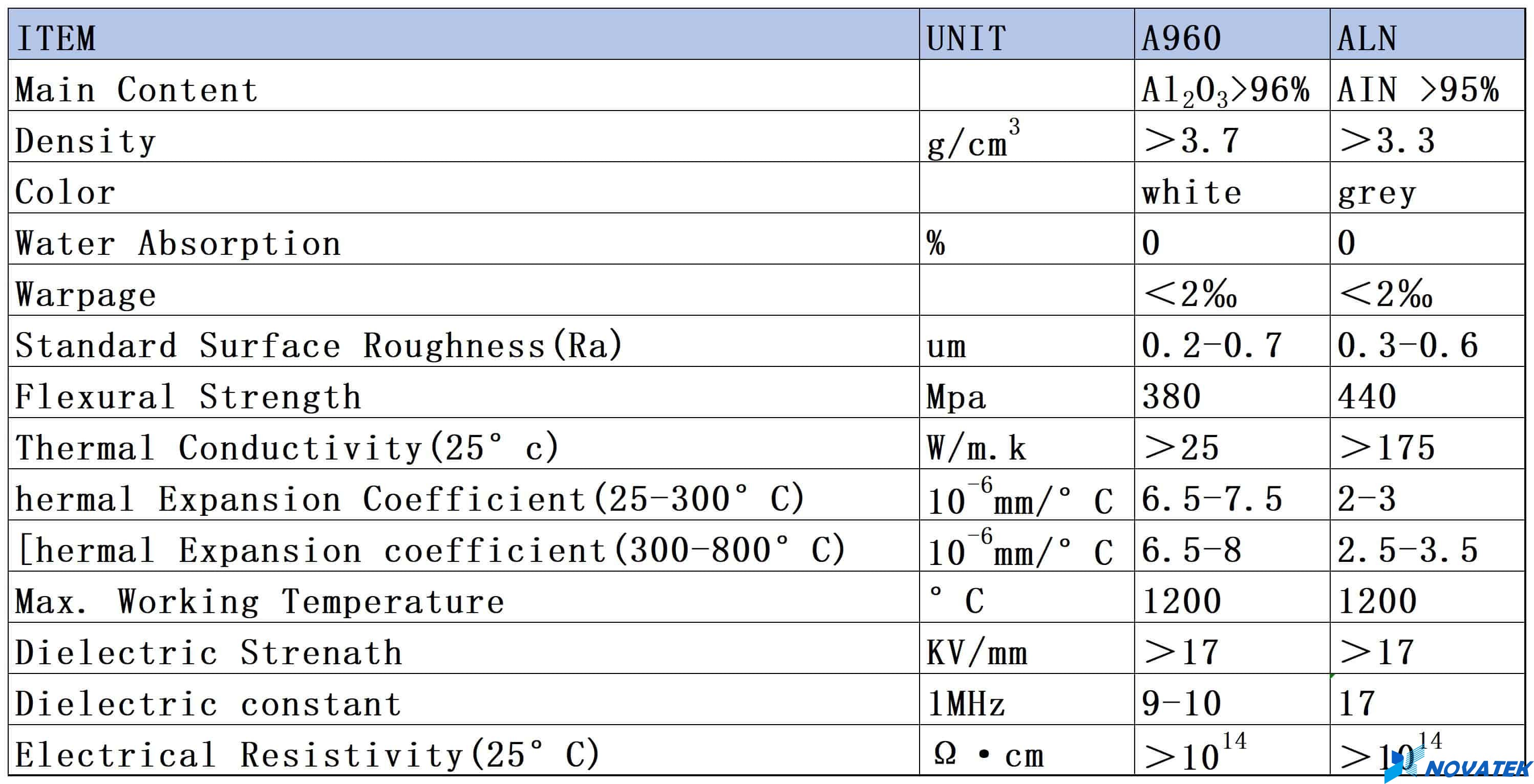

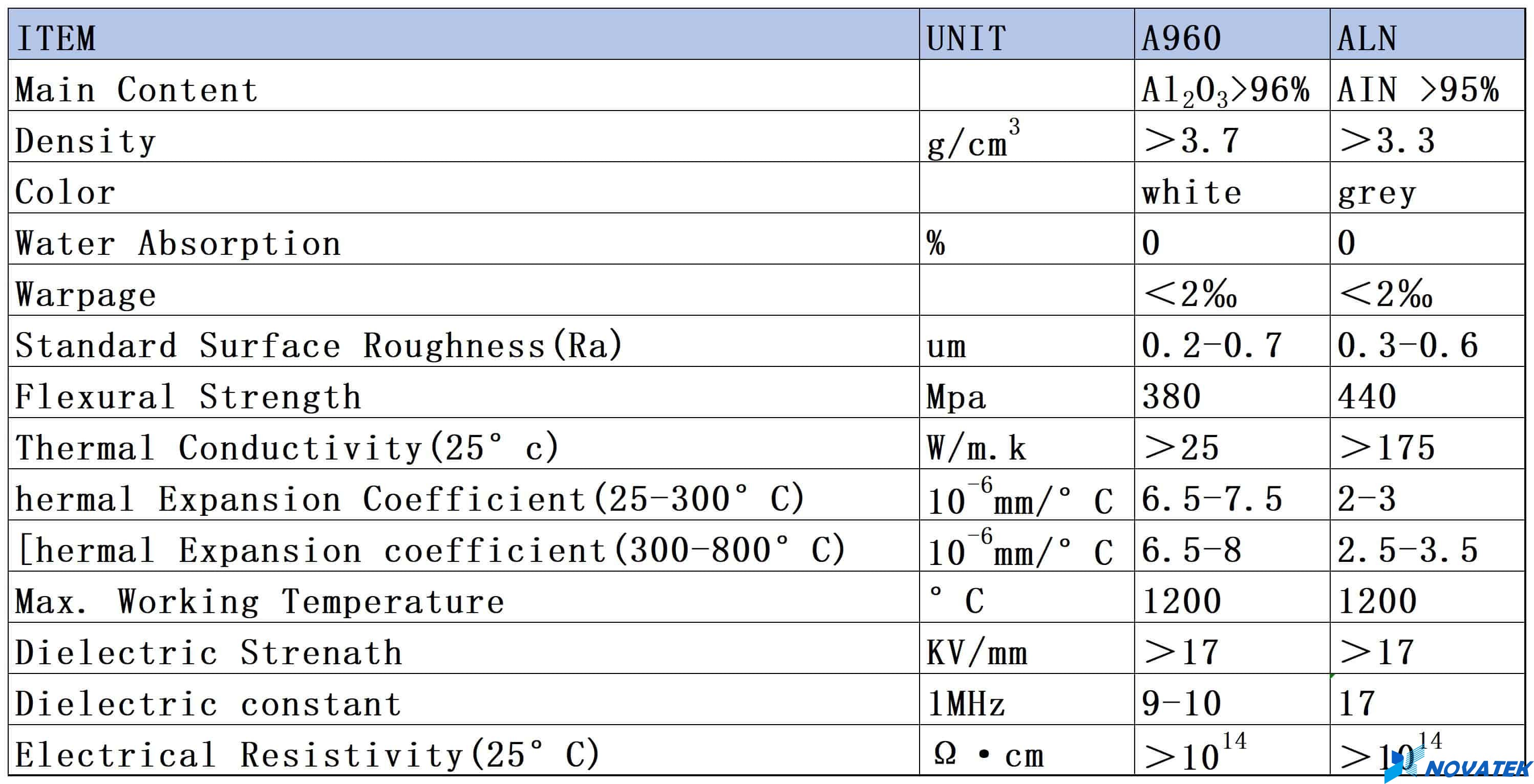

▼ Properties

|