|

Detailed introduction/parameters/applications/functions/maintenance of Si3N4 Silicon nitride ceramic nozzle

▼Description of Ceramic Substrates DPC

Direct Plated Copper (DPC) is the newest development in the field of Ceramic Substrate PCBs and using this method can result in copper thickness' ranging from 10um (≈ 1/3oz) to 140um (4oz). With DPC track printing and etching is then performed with the thin Copper allowing for very fine tracks and reduced undercutting.

DPC Ceramic Substrateis the long-proven standard for power electronic modules in industrial, home-appliances and automotive applications. Unipretec ceramic substrates DPC have an excellent performance/cost efficiency ratio. The great heat conductivity ofAl2O3 (25 W/mK)andAlN (175 W/mK)as well as the high heat capacity make the substrate irreplaceable in power electronics. The thick copper foils offer extremely good electrical and thermal conductivity and form an outstanding base for the soldering and wire bonding processes.

▼Main performance advantages

| ✔High Mechanical Strength |

✔Good Thermal Conductivity |

| ✔Excellent Electrical Insulation |

✔Outstanding Chemical Stability |

| ✔Extremely High Service Temperature |

✔Small Thermal Expansion Coefficient |

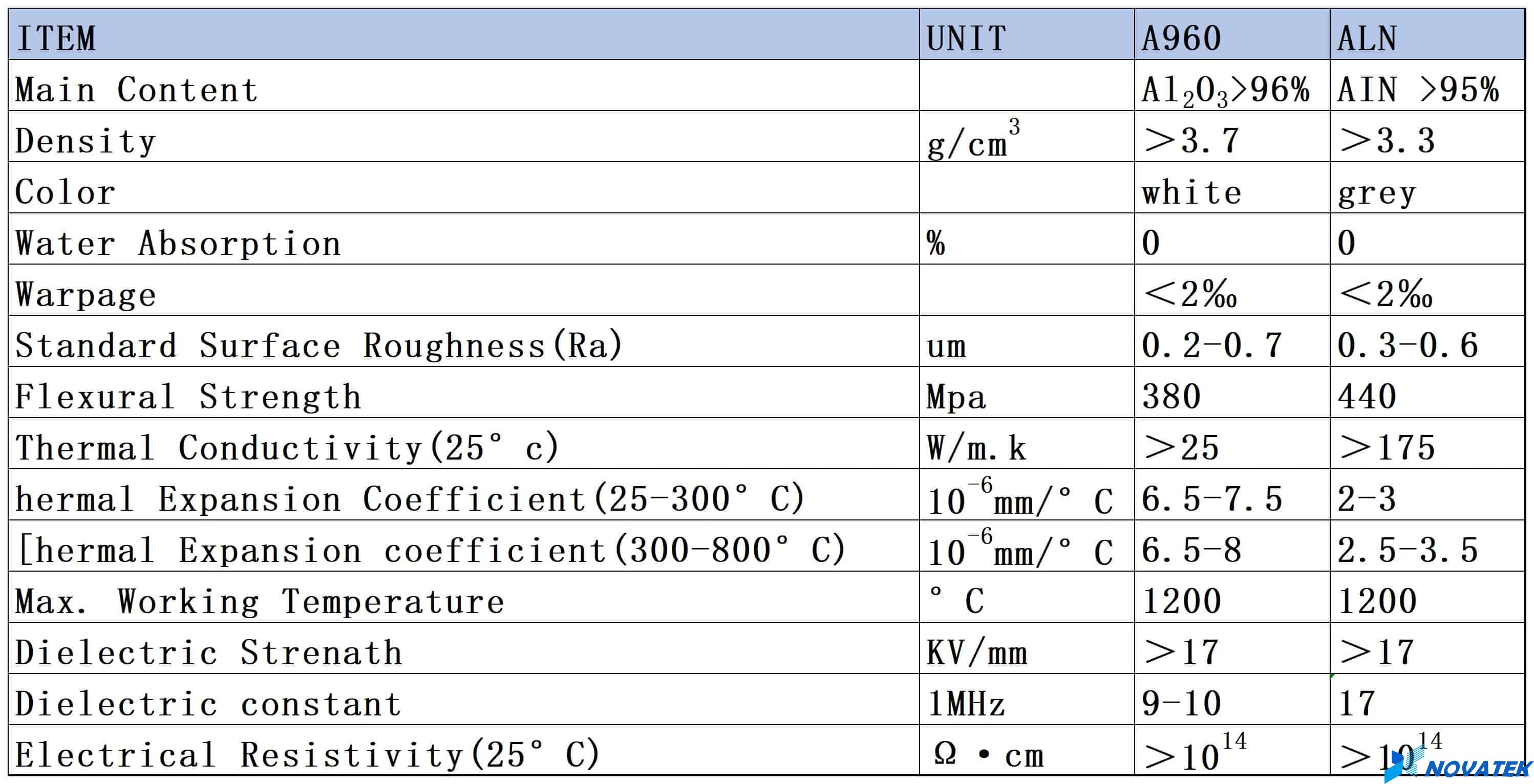

▼Properties of Ceramic Substrates

▼Applications of DPC Ceramic SubstratesDPC ceramicsubstrates are recommended for power electronic modules (e.g. current inverters) using MOSFETs or IGBT semiconductor elements and diodes for widespread application fields in the industrial sector: electric motor drives, e.g. in tooling machines, cranes, textile-processing equipment, automation equipment, etc.

- Pumps

- Welding machines

- Electrical industrial vehicles (e.g. power drives for forklifts)

- Induction heating

- Industrial drives (e.g. escalators, conveyor belts, elevators, robots, and servo drives)

- Uninterruptable power supply to. data centers, hospitals, etc.

- Energy technology (e.g. photovoltaics, wind turbines, and energy distribution)

- White goods (e.g. air conditioners, washing machines, refrigerators, and warm water pumps)

- Automotive and traction

As high-performance circuit carriers for power electronic applications:

In such groups as power steering, start-stop systems, air conditioning compressors, water pumps, oil pumps, brakes, etc;Converters for hybrid or electrical power train; Battery chargers; Inductive charging systems; DC-DC converters; Rail vehicles such as locomotives, subway trains, trams and cable cars, etc; Communications. |